JK Cement Ltd of India has contracted ThyssenKrupp Polysius to supply three new grinding plants equipped with POLYCOM highpressure grinding rolls. The...

Loesche Mills for cement raw material. 2 Cement raw material has been almost exclusively ground in roller mills (vertical airswept grinding mills) since the second ...

Raw material preparation aims to ... The production of one ton of portland cement requires more than ton of raw ... If raw material grinding is ...

2 Cement raw material has been almost exclusively ground in roller mills (vertical airswept grinding mills) since the second half of the 20th century.

Raw material grinding is one of the processes used to manufacture cement of highest quality.

Cement grinding Vertical roller mills versus ball ... easily obtained in raw material grinding in a ... when grinding cement than when grinding raw ...

Raw material grinding in a cement plant – Grinding Mill China . Raw material grinding in a cement plant. Raw material grinding is .

CEMENT RAW MATERIALS PLANT SIZES. The coordinates of the grinding table diameter and number of rollers can be read off from the table. The x .

Cement Raw Material Grinding Mill, Wholesale Various High Quality Cement Raw Material Grinding Mill Products from Global Cement Raw Material Grinding Mill .

Another essential raw material is gypsum, some 5 percent of which is added to the burned cement clinker during grinding to control the setting time of the cement.

Cement Production, raw material and ingredients for cement... The main raw material to produce Portland cement are lime materials and clayey materials, and ...

Raw mill is mainly used in grinding raw materials and final products in cement plant. It is also suitable for grinding various ores and other materials in the ...

cement raw material grinding process About jade CCTV News CNTV English. About jade. ... speckled or streaky material. It is not until the cutting process ...

LoescheMills for cement raw material LOESCHE Cement raw material has been almost exclusively ground in ... 1928 The first springloaded airswept grinding mill in ....

Optimization of cement raw material ball mill dry grinding [Genç Ömürden] on *FREE* shipping on qualifying offers. .

Cement is the basic ingredient of construction and the most widely used construction material. Its manufacturing includes extraction, proportioning, grinding,

Portland Cement Manufacturing ... raw material processing operations differ somewhat for ... water is added to the raw mill during the grinding of the raw ...

History. The history of the development of the technology of raw material grinding defines the early history of cement technology. Other stages of cement manufacture ...

Maximum throughput rates and drive powers, smallest possible construction size and high availability are the essential demands on a cement raw material grinding plant ...

Raw Material Grinding. The desired raw mix of crushed raw material and the additional components required for the type of cement, silica sand and iron ore, is ...

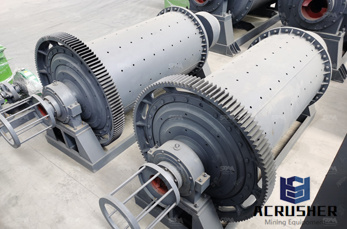

Ball Mill > Grinding drying > Raw. For grinding raw material and coal the airswept ball mills are one proven having the lowest investment costs of all grinding ...

grinding aids for cement and raw material mills Grinding. From raw materials Extracting raw materials Raw material . World Business Council for Sustainable ...

Ball mills are still used in 12–13 % of all raw material grinding applications, such as the ... also been used for grinding cement raw material. ...

Manufacturing Process Of Cement. Quick ... method is used to reclaim and obtain high efficiency raw material ... yard/clinker silo for cement grinding.

WhatsApp)

WhatsApp)