C powders by highenergy ball milling and further heat treatment. The milling process was carried out in a planetary ball mill. Following the milling process, powder ...

Prediction of specific energy consumption in milling process using some physical and mechanical properties of alfalfa ... the compression behavior of powder ...

High energy ball milling, matrix, reinforcement, hard phase ... The best milling results are achieved using a high ball to powder ratio and big milling balls.

Improve Milling Through Better Powder ... who related microcracks from blasting to energy use in ... Milling tests of increased powder factor are often ...

SWECO VibroEnergy Grinding Mills are the most versatile line of ... The low energy condition is reserved for wet milling whereas the higher energy mode can be used ...

low power consumption ore grinding mill powder grinding mill_large capacity cement vertical roller millvertical roller mill worldcrushers. vertical mill,vertical ...

Electrical energy savings in flour milling September 1, ... Energy use in milling extends from the beginning to end of the transformation process.

CCE Technologies, Inc ... Abrasives, Powder Coatings and other fine powder applications; ... Dense Phase Fluid Energy Milling Product Catalog:

Blasting has an important impact on mining and milling well beyond ... blasting energy input ... the powder factor of .31 kwh/ton. From an energy ...

Effects of Different Milling Processes on Properties of Douglasfir Forest Residuals ... • HM2ACM2BM8 wood powder showed lower energy consumption

Provide an insight into interactions between tungsten powder and surrounding in a vial during high energy ball milling. • Reveal morphology and microstructure of ...

power consumption for coal grinding ... Vertical mill for Coal Powder Grinding, ... The specific energy consumption of an ATOX coal mill based on the Hardgrove

How to Use a Ball Mill Safely ... Low agitator tip speeds significantly reduce wear and energy use The other ... How much should I use (Ball to powder ...

Calculated on 60% power consumption, ... Energy Efficient CNC Milling Machine from DATRON saves electricity, ... Energy Efficient CNC equals savings:

On Mar 1, 1990 Hitoshi Hashimoto (and others) published: Model Simulation of Energy Consumption during Vibratory Ball Milling of Metal Powder

Powder TechnololY, 38 (1984) 275 293 275 PhysicoChemical Aspects of Grinding: a Review of Use of Additives ... Distribution of energy in a ball mill ...

Reduce Energy Consumption: ... VM series Vertical Grinding Mill is a kind of large scale powder mill which is designed specially to solve the problems of low capacity ...

The 6 th International Conference on Manufacturing Research (ICMR08) Brunel University, UK, 911 th September 2008 HIGH ENERGY MILLING OF MICRO MAGNETIC POWDER FOR

A study of the oxidation of ZrB 2 powders during highenergy ball, energy use milling powder,Recently, it has been shown that highenergy ballmilling in dry ...

Powder Mill Power Equipment Sale In Use, Crusher. powder mill power equipment sale in use; Double equipment; About Double; Double service; Contact double; mesin ...

Mill (grinding) Attrition Mill; A ... Compared to ball mills HPGRs achieve a 30 to 50% lower specific energy consumption, ... powder mill produces gunpowder; Ball mill;

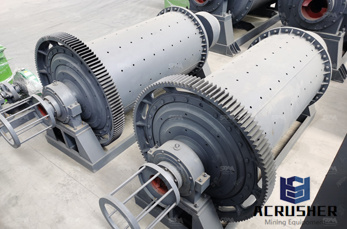

Ball millingthe method of producing manganese metal powder. The technological production process of manganese metal powder. Ball mill is the ... energy consumption ...

Energy Use Milling Powder energy use milling powder. Ball mill Wikipedia, the free encyclopedia. A ball mill is a type of grinder used to ...

powder mill energy plant. Home; ... Energy Consumption for the Production of Metal Powders . .... is not a typical production plant in the industry. .....

WhatsApp)

WhatsApp)